What We Offer

Our company is a physical manufacturer that can undertake the design and manufacturing of working conditions and requirements proposed by customers.

Products

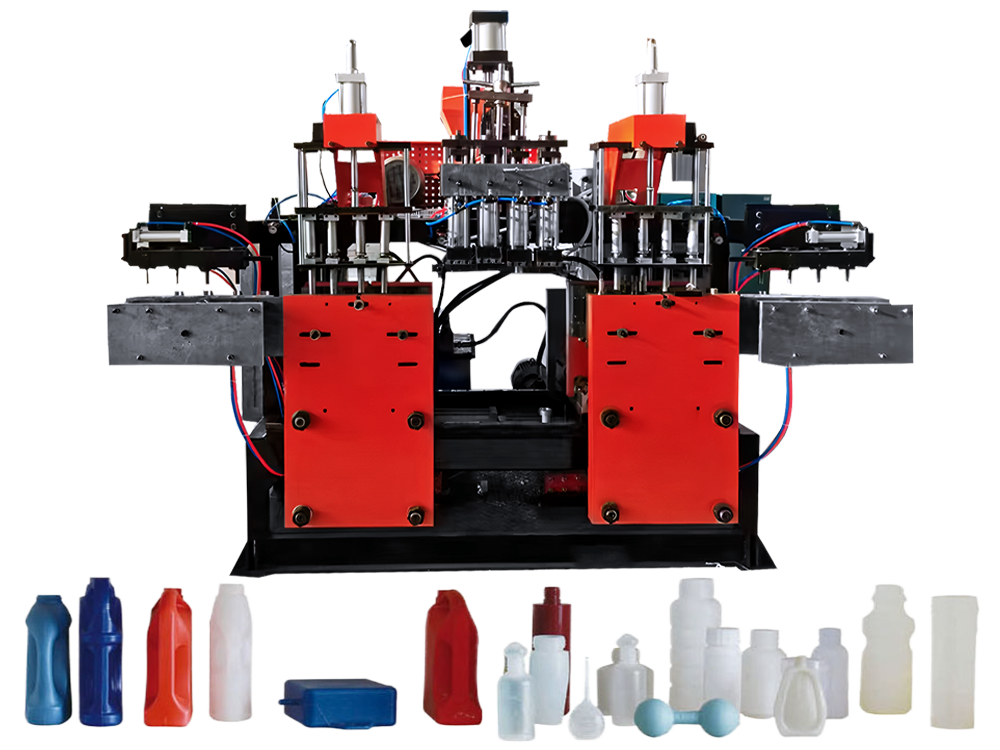

We specialize in designing, developing, manufacturing, and selling dozens of series and hundreds of specifications of fully automatic hollow molding blow molding machines and fully automatic bottle blowing machines.Product quality is guaranteed and traceable.

Establishment time

Current occupied area

Annual transaction volume

Exporting countries and regions

The company focuses on designing, developing, manufacturing, and selling dozens of series and hundreds of specifications of fully automatic hollow molding blow molding machines and fully automatic bottle blowing machines. Our main products include: blending blow molding machine, PET blow molding machine, high-speed automatic blow molding machine, fully automatic blow molding machine, semi-automatic blow molding machine, hollow blow molding machine, storage tank hollow blow molding machine, five gallon water bucket blow molding machine, and various plastic auxiliary equipment.

View MoreGLOBAL NETWORK

Providing Our Customers

with Best Services

Our company is a physical manufacturer that can undertake the design and manufacturing of working conditions and requirements proposed by customers. We have multiple inspection and testing personnel, and all products have passed excellent quality inspections, ensuring you can rest assured of their quality. Our company has multiple production and processing equipment, each of which has undergone strict production testing standards.Quality first, integrity-based, and innovative to win "are our principles, providing products and services to customers. We listen carefully to each customer's requirements and needs, design and produce products according to their different needs, and help you obtain ideal products. We have a complete after-sales service system, allowing you to purchase with confidence. Our customer service is available 24 hours a day to provide consultation services and solve after-sales related problems for you.

Welcome to visit the factory and discuss cooperation.

Blogs & Articles

We carefully listen to every customer's requirements and needs, design and produce products according to their different needs, and help you obtain the ideal product.

2025-02-07

What are the application industries of HDPE plastic drums

2025-02-07

What is the general service life of automotive urea plastic barrels

2025-02-07

What are the environmental requirements for storing chemical drums

2025-02-07

Key points for stacking plastic square buckets in the chemical industry

Baitong Plastic Machinery

Baitong Plastic Machinery

Baitong Plastic Machinery